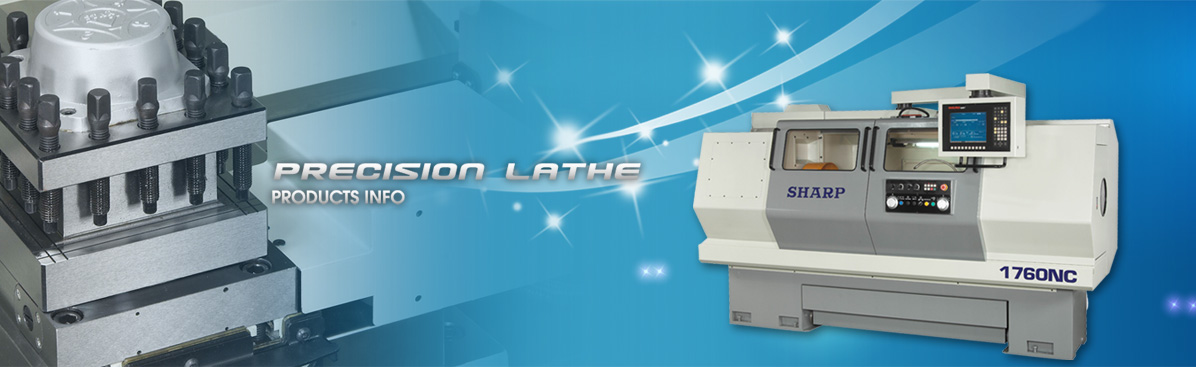

CNC LATHE (Flat-bed type)

Model: 1440NC

FEATURES:

˙FANUC, FAGOR, SIEMENS, SYNTEC control are available.

˙CNC and manual operation.

˙Electronic hand-wheels for manual turning.

˙Teach in mode.

˙Integrated PLC.

˙Semi-automatic, automatic (cycle) and part program modes.

˙Rapid traverse.

˙Automatic home searching.

˙30-2000 R.P.M. infinite variable spindle speed.

˙38mm. 1-1/2inch hole through spindles.

˙2-point supported spindle using 2 precision taper roller bearings.

˙All geared headstock, main gears are made from Chromium, Nickel, molybdenum alloy steel and are case hardened and “REISHAUER” ground.

˙Forced spray lubrication system used for headstock.

˙High precision ball-screws.

˙Hardened of bed-way & cross ways meet HB 450.

˙Auto lubrication unit for all slide-ways surface and ball-screws.

˙5HP 3.5KW Main motor or 7.5HP 5.7kw main servo motor.

HEADSTOCK

˙The headstock is made of high quality cast iron (FC30) all shafts and gears are of high tensile tensil steel and are hardened and ground.

˙3 spindle speeds 30-2000 rpm. Low speed provides High torque output for heavy duty cutting. Hi speed is for finish cutting.

˙Hardened and ground main spindle is supported by precision taper roller bearing.

˙Headstock have inner oil reservoir in which lubrication worked by splashing lubricant.

BED WAY

˙Meehanite cast iron bed is heavily ribbed.

˙The bed ways are induction hardened to HS70 and precision ground.

CARRIAGE

˙Automatic lubrication system continuously supplies lubricating oil to carriage and cross-slide.

TAILSTOCK

˙Tailstock is of rigid construction and features super tight clamp locked by clamp lever.

˙M.T. #3 barrel internal taper provides heavy support for live centers or tip center.

˙The quill is hardened and ground with inches and metric graduations.

|

|

|

pElectrical box

|

|

pChip tray Easily to remove the chip front of the lathe.

|

pOPERATOR BOX (OPTIONAL) - Dual hand wheels in front of CNC lathe easily to control in manual mode. - Operator box can move smoothly. |

|

|

|

|

|

|

pElectrical 4 way toolpost (OPTIONAL) |

pHydraulic Tailstock |

pQuick change tool post |

STANDARD ACCESSORIES:

1. CNC control system.

2. 3 Jaw chuck 6 inch (165mm) with backplate.

3. Manual Quick change tool post.

4. Steady rest

5. Automatic lubrication system

6. Coolant pump system

7. Electrical hand wheel

8. Work lamp

9. Signal lamp

10. Safety guard

11. Toolbox with tools.

12. Center sleeve

13. Two dead centers

14. Camlock spindle wrench.

15. Oil gun

16. Optional manual and part list

OPTIONAL ACCESSORIES:

1. 3-jaw strong scroll chuck

2. 4-jaw independent chuck

3. Face plate

4. Follow rest

5. Electrical 4 way tool post

6. Live center M.T.#3.

7. Drilling chuck ½in. (13mm)

8. Hydraulic chuck system 3 jaw 6" chuck

9. Hydraulic tailstock

10. Transformer

11. CE Standard Equipment

|

BRIEF SPECIFICATION |

|||

|

MODEL |

1440NC |

||

|

NOMINAL SIZE |

|||

|

Swing over Bed |

356mm 14in |

||

|

High of center |

176mm 6-7/8in |

||

|

Swing over Cross Slide |

172mm 6.7in |

||

|

Distance Between Centers |

1000mm 40in |

||

|

Width of Bedways |

206mm 8-1/2in |

||

|

SPINDLE |

|||

|

Number of spindle speeds |

3 / 1(Opt.) |

||

|

Speed range |

HI |

2000~410 RPM |

30-2000RPM Servo motor(Opt.) |

|

MID |

540~110 RPM |

||

|

LO |

140~30 RPM |

||

|

Hole through spindle |

38mm 1-1/2in |

||

|

Spindle nose |

D1-4 CAMLOCK |

||

|

Taper of spindle bore |

M.T.#5 |

||

|

TAIL STOCK |

|||

|

Total travel of tailstock barrel |

100mm 3-15/16in |

||

|

Taper in tailstock barrel |

M.T.#3 |

||

|

Diameter of barrel |

Dia. 45mm 1-3/4in |

||

|

X-axis |

|||

|

Travel |

180mm 7in |

||

|

Rapid travel |

6m/min |

||

|

Ballscrew Dia. |

25mm Pitch5 |

||

|

Max servo force |

6.3Nm |

||

|

Z-axis |

|||

|

Travel |

840mm 33-1/2in |

||

|

Rapid travel |

6m/min |

||

|

Ballscrew Dia. |

32mm Pitch5 |

||

|

Max servo force |

6.3Nm |

||

|

TOOLPOST |

|||

|

Number of tools |

4T |

||

|

Shank Tool |

20 mm |

||

|

Cutting Distance |

800~950mm |

||

|

ELECTRICAL EQUIPMENT |

|||

|

Main spindle motor |

5HP motor 3.5KW /Servo motor 7.5HP 5.7KW(Opt.) |

||

|

Axis servo motor |

Servo motor 1.6HP 1.2KW |

||

|

Auto lubrication |

2L |

||

|

Coolant pump |

1/8HP |

||

|

PACKING SIZE |

|||

|

SPACE |

2070 X 1360 X 1683mm |

||

|

PACKING SIZE |

2300 x 1460 x 2120mm |

||

|

Machine net weight |

1200 kg |

||

|

Gross weight |

1300 kg |

||

We reverse the right to modify and improve our products.